To stay on top of things in the “jungle” of zirconium oxide types

and to select the right indication, it’s important to gain an

understanding of the mechanical parameters. In particular it’s worth taking a closer look at the highly translucent zirconium oxides for veneer-free monolithic restorations.

So the KIC value provides information on how robustly an all-ceramic behaves, e.g. during processing in the laboratory or during insertion by the dentist.

The classic, high-strength 3Y TZP zirconium oxide grades generally possess a high fracture toughness (>5 MPa√m)—an essential factor for their clinical success. The super high translucents (SHT) 5Y TZP have a lower initial KIC, which is recommended for 3-unit molar bridges with at least >3 MPa√m . In this way, the crystalline structure of the 5Y TZPs offers little to no potential for phase transformation and therefore for strengthening.

DD cube ONE® is the ideal choice for long-span bridges with high translucency and reliable robustness!

Since 2010, more than 16 million tooth elements have been made from our proven, high-strength 3Y-TZP zirconium oxide

types DD Bio Z and DD Bio ZX2. Thanks to the documented clinical success with these types, our developers have defined a fracture toughness of KIC > 9 MPa√m for the fracture protection factor.

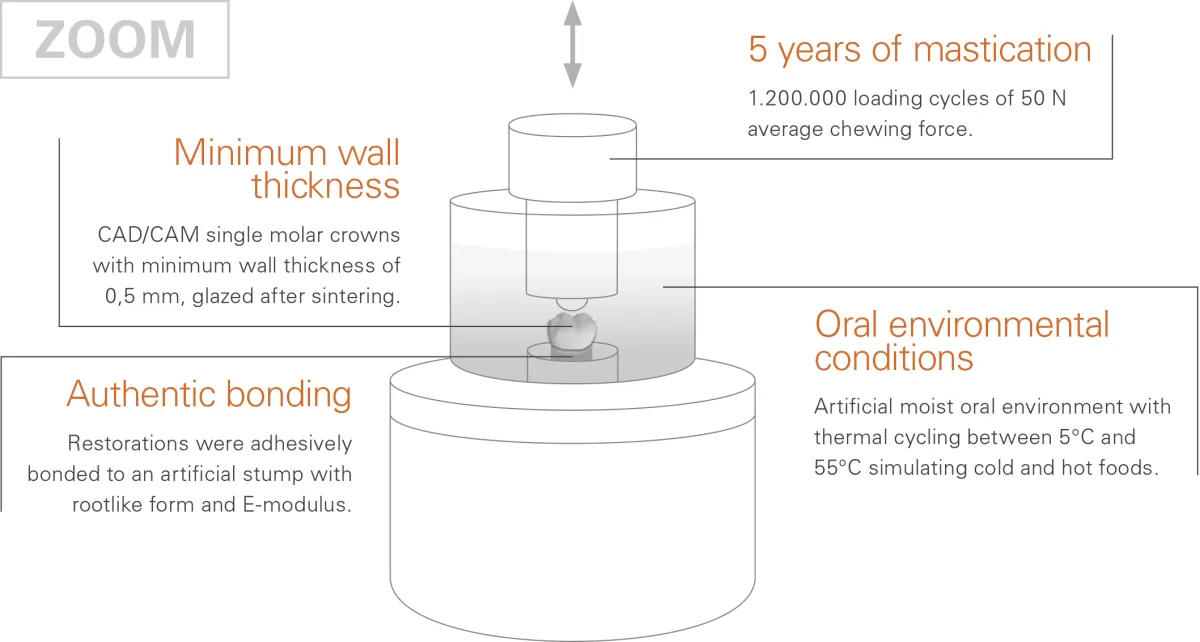

This test setup simulates the mechanical and thermal stresses to which a dental restoration in the patient's mouth is exposed for a period of 5 years.

DD cube ONE® ML (4Y TZP) has a hybrid crystal structure of about 30% cubic and 70% tetragonal crystals. The KIC is ≈10 MPa√m SEVNB. Aluminum oxide (Al2O3) was added in a balanced concentration to positively influence the aging behavior. The cubic, large crystals are responsible for increasing translucency. The KIC value of fracture toughness is just as high in the incisal area of the multilayer variant as it is in the rest of the body. This should provide the best possible security even when corrections are made to the occlusal surfaces.