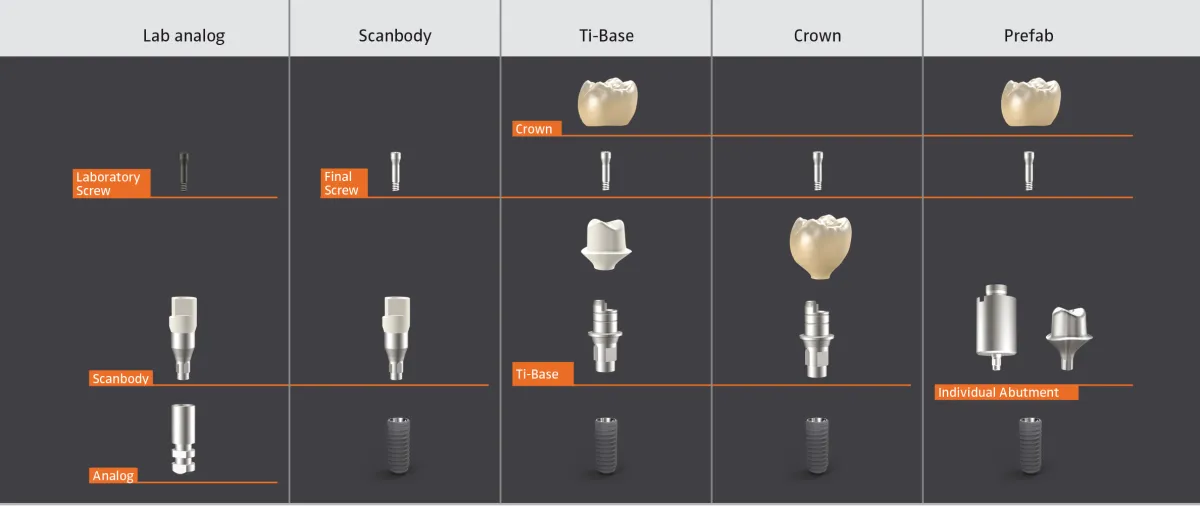

In the digital production of patient-specific abutments, the design is created in "backward planning" - starting from the ideal crown shape. By optimally designing the transition from implant to crown anatomy, the individual abutment plays a significant role in the overall esthetics of the restoration. Form and function allow the gingiva to take on a natural shape at the soft tissue emergence and imitate root cross-sections - similar to the natural tooth. Anatomical emergence profiles can thus be planned individually.

In order to guarantee perfect milling results when using our DD Solid Connect® Prefabs, we have developed a machine holder system that enables low-vibration and torsion-resistant machining. The high-precision implant interface is not exposed to mechanical loads at any time. The precise fit into the original implant is thus ensured.

Our system is available for different machines in combination with various CAM software solutions.

If your machine / CAM software combination is not listed, please contact us. Together we will find a solution.