The sinter furnace – the final touch for aesthetic restorations

The cubic zirconium oxides provide the best prerequisites to convince visually. However, perfect aesthetics can only be achieved through a well-controlled sintering process. In addition to the fact that undesirable discoloration can occur (see in more detail in our DD journal: https://www.dentaldirekt.de/en/dd-journal/dd-phoenix), the sintering end temperature and the filling of the furnace play an important role.

Precision with regard to the exact sintering end temperature

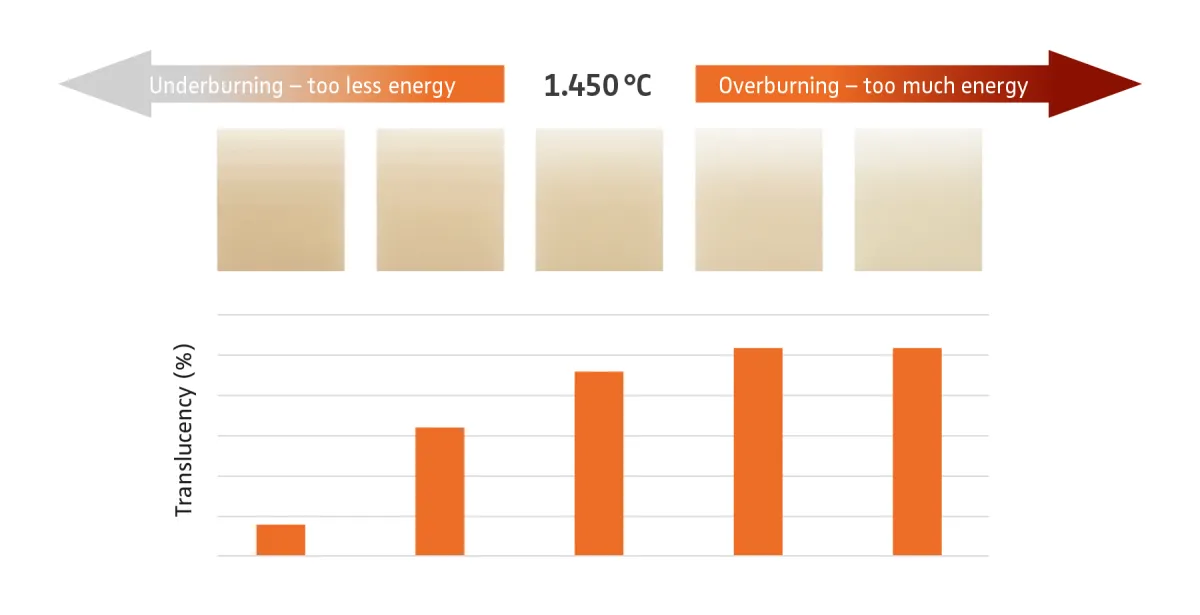

As the sintering temperature rises, and thus the input of thermal energy, grain growth increases, which results in comparatively less scattering or refraction of the incident light and thus increases the translucency. Furthermore, the chroma of the restoration changes because the coloring materials are "incorporated" differently into the structure of the material due to the increased temperature.

For example, a temperature that is too low would lead to the individual layers in a multilayer zirconia not bonding properly and not forming the desired color. A temperature that is too high would lead to fading. Fig. 1 illustrates the influence of thermal energy using blank-high samples of DD cubeONE® ML in A3.

Fig. 1: Influence of the sintering end temperature on the optics/translucency using the example DD cube ONE® ML A3, sintered samples in blank height - thickness 1mm. The chemical composition of the DD cube ONE® ML is adjusted to achieve the ideal color, strength and translucency at a final temperature of 1.450 °C. The color is optimized to match the VITA® color reference after glaze firing. If the final temperature is below 1.450 °C, the result appears darker and more opaque and the single edges of the transition layers become visible. If the final temperature is above 1.450 °C, the result is lighter/paler than desired.

DD tip:

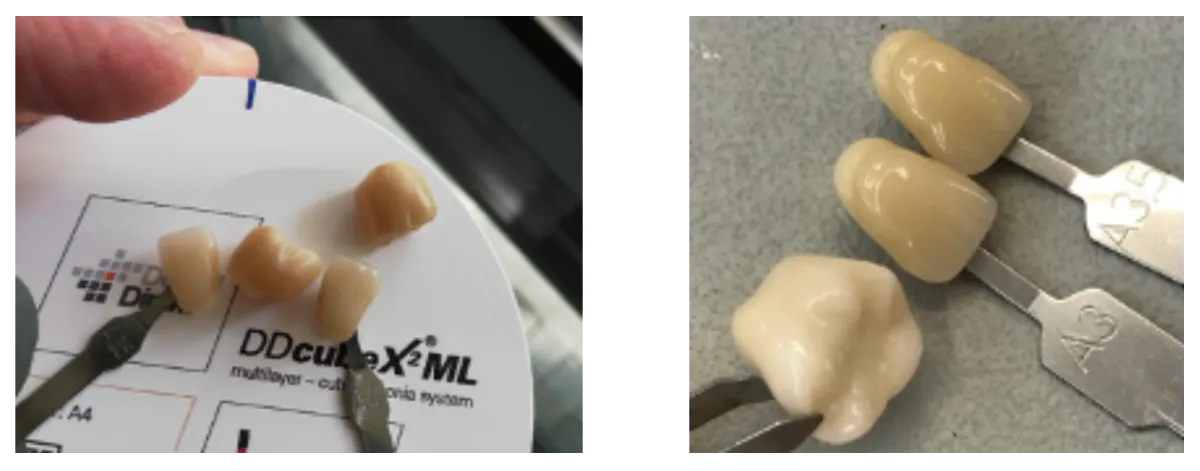

One way to determine the firing accuracy of your sinter furnace is the PTCR test (process temperature control ring). The PTCR is a ceramic ring that shrinks proportionally to the heat input during a sintering cycle. The PTCR manufacturer provides a specific sintering curve for each ring type, for which the shrinkage is precisely determined. Against the background of the final dimension of the ring, the final furnace temperature can be determined with an accuracy of +/- 10°C using temperature tables. If necessary, the knowledge gained can be used to recalibrate the furnace to avoid unpleasant surprises as shown in Fig. 2.

Fig. 2: Underborn example: DD cubeX2® ML crown in A4 (left), overburn example: DD cube ONE® ML crown in A3 (right)

DD tip:

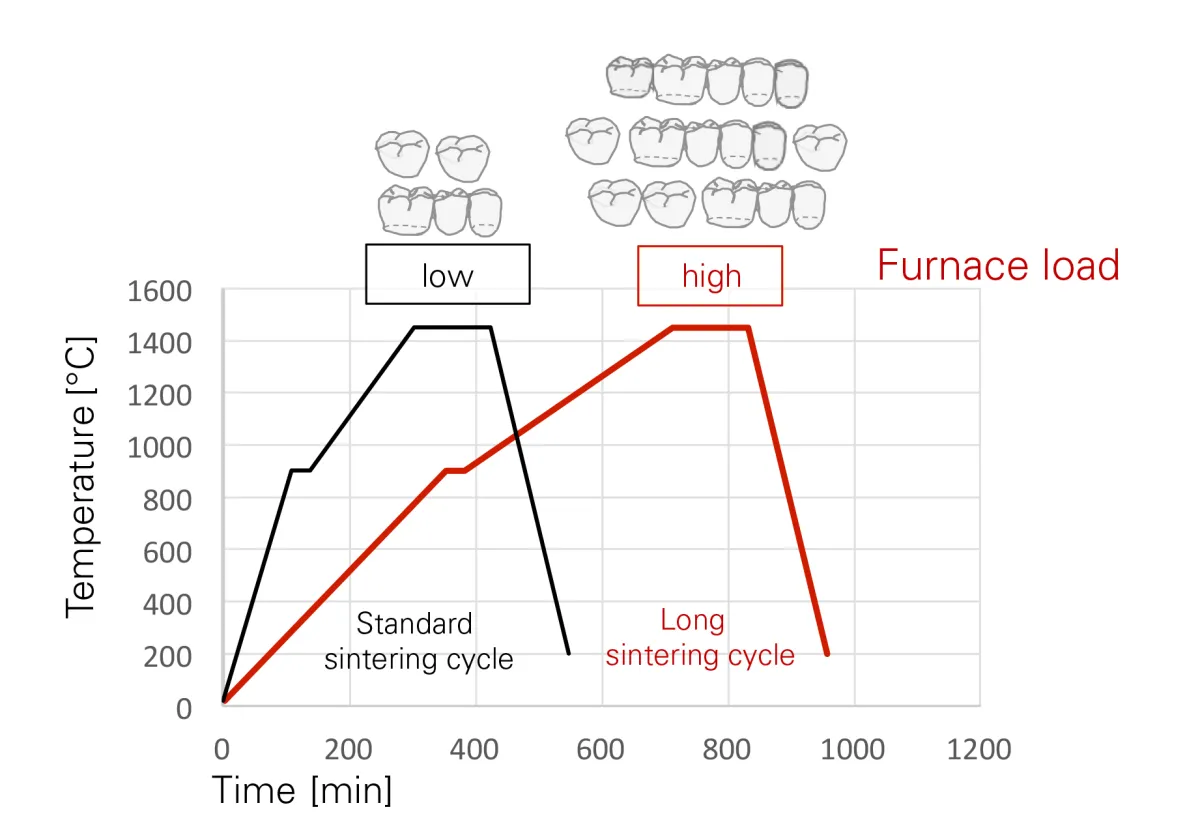

In case of a high furnace load and/or solid constructions, it is recommended to select a sintering program with longer heat-up phases (see Fig. 3). Slower heating rates may help to achieve uniform results from one firing to the next.

CONCLUSION

As the sintering process - as explained - has a considerable influence on the color, translucency and reproducibility of the zirconia work, the investment in a high-quality and reliable sintering furnace pays off.

With our AUSTROMATTM 674iTM »ONLINE EDITION« you get the final touch

- High temperature furnace up to 1.560 °C

- Sintering, glazing and crystallization under atmosphere in one device

- Speed cycle programming

- Space for all common bridge sizes or up to 40 units in one plane (Ø 100mm)

- Second sintering plane optional

»The right sinter furnace makes the difference for your work and constructions. The online connectivity of the AustromatTM 674iTM allows me to advise you as a customer even more effectivley by having direct access to the parameters of your furnace - that's Support 4.0 for me.«