Nesting (/ˈnɛstɪŋ/): When used in the field of dental CAD/CAM, the term nesting describes how the CAD designs are positioned in the milling blank. The aim is to use the blank surface in an ideal way that saves space. Bars and sinter supports are set and undercuts are both visualized and optimized.

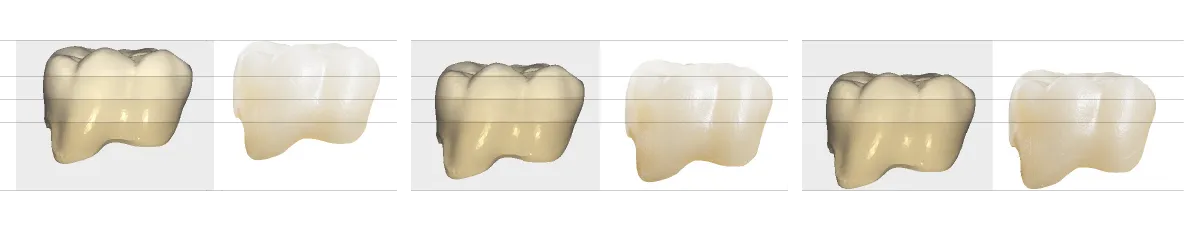

Nesting is particularly important when processing multilayer blanks. Transferring the layering diagram into the nesting software (CAM software or Exocad “In-CAD Nesting Module”) allows you to visualize the color gradient of the crowns and bridges. This allows you to plan better and supports the work process on the screen. It ensures that you have full control over the brightness value and color intensity of crowns and bridges in the anterior and posterior region.

DD Multilayer blanks consist of five main layers. The decisive factor for a top blank is coordinating chemistry and crystal size in the layers. Our concept guarantees the best mechanical properties, homogeneous sinter shrinkage and uniform CTE over all layers for safe, and aesthetically pleasing patient care.

Diversity wins.

Dental Direkt – the complete provider in the dental sector